Trebi is 'ABB Value Provider' Find out more →

By automating the supply chain we simplify the procedure to obtain the process and product certification.

Thanks to total control, the human factor is reduced to the benefit of the workpieces quality: always the same and in compliance with the specifications.

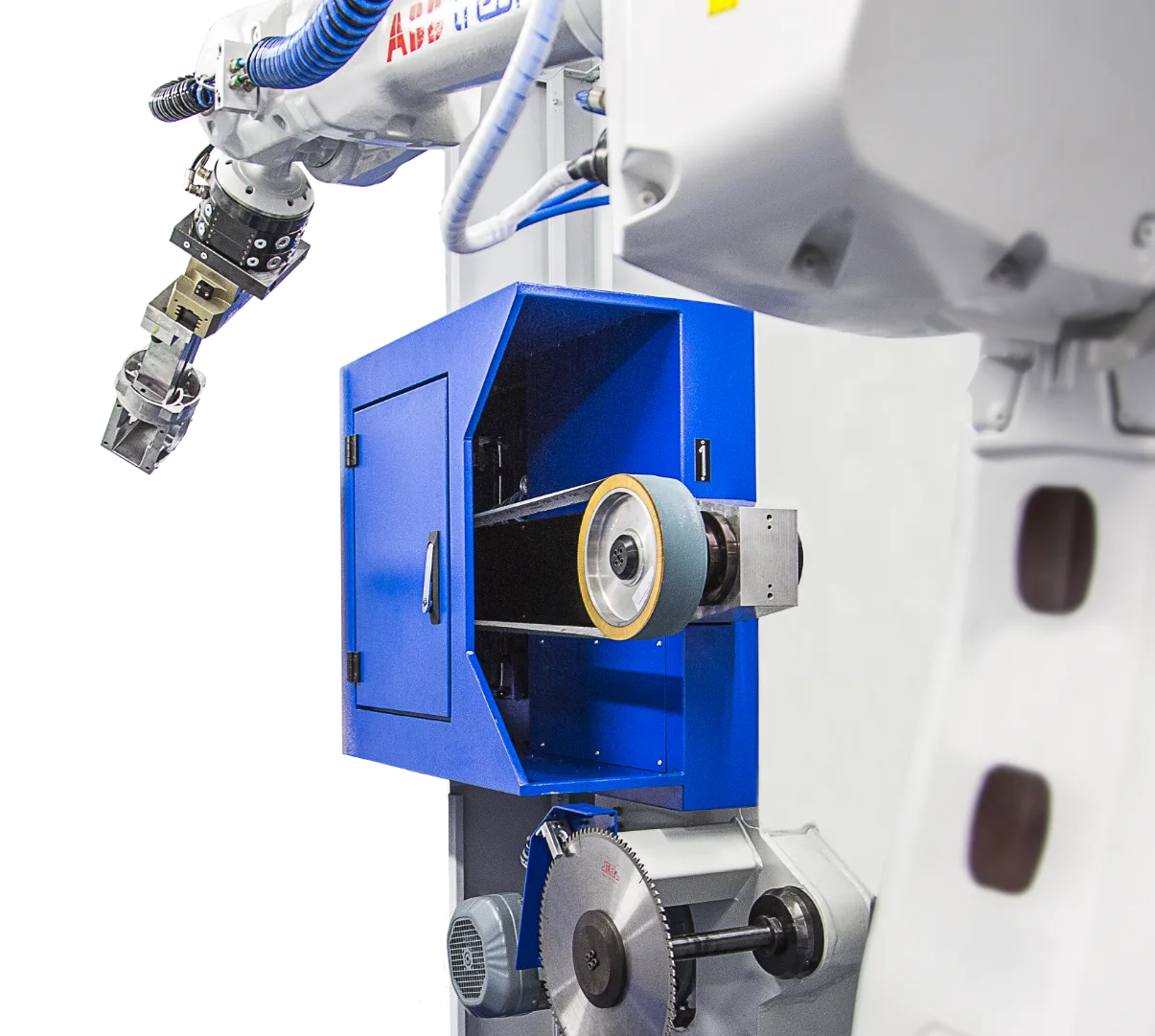

Our machines can be installed inside the casting cell, in continuous flow, thus between casting and finishing. This approach streamlines the logistics between the phases and makes the machining of the workpieces much more effective. Furthermore, we dedicate dozens of hours to simulations and the result is: process optimization and zero dead times.

To offer a comfortable and safe working environment, according to the latest regulations (ATEX), we manufacture totally enclosed machines. Thanks to this solution, the time dedicated to installation is reduced, the daily cleaning is simplified, and the acoustic comfort is better throughout the work area

To achieve the shortest cycle times, we use highly rigid robots. The reduction of vibrations during machining allows us to improve performance by cutting down on time and extending the life of the tools, for constant production over time and to its full potential.

Discover the economic benefits of automating the deburring process achieved by our partners

Download the Case History

Get a customised simulation of consumption, cycle times and the finishing level of the workpiece before the system becomes operational.

Ask for the simulation

We offer systems for different sectors with a common denominator: total control. Experience has us allowed to develop solutions to monitor process efficiency and quality. The adaptation of emerging technologies also means the right information at the right time.

Automotive

Mechanic

Fittings

Taps

Furniture

Ligthing

Handles

Manholes